Fibers, Vol. 11, Pages 49: Controllable Water-Triggered Degradation of PCL Solution-Blown Nanofibrous Webs Made Possible by Lipase Enzyme Entrapment

Fibers doi: 10.3390/fib11060049

Authors: Fnu Asaduzzaman Sonja Salmon

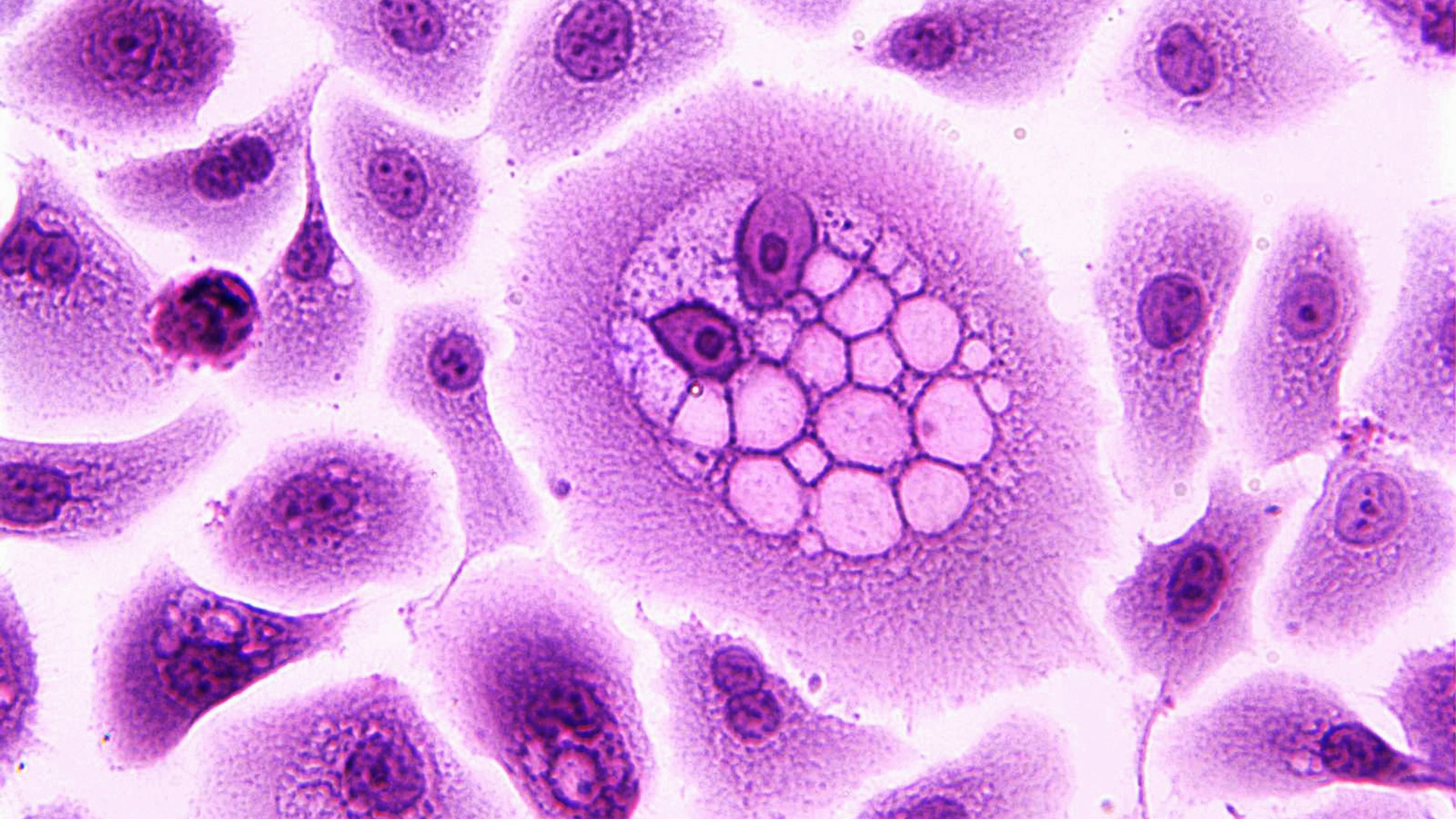

Polymers in nanofibrous forms offer new opportunities for achieving triggered polymer degradation, which is important for functional and environmental reasons. The polycaprolactone (PCL) nanofibrous nonwoven polymer webs developed in this work by solution blow spinning with entrapped enzymes were completely, rapidly and controllably degraded when triggered by exposure to water. Lipase (CALB) from Candida antarctica was successfully entrapped in the PCL webs via an enzyme-compatible water-in-oil emulsion in the PCL–chloroform spinning solution with added surfactant. Protein (enzyme) in the nanofibrous webs was detected by Fourier Transform Infrared Spectroscopy (FTIR), while time of flight-secondary ion mass spectroscopy (ToF-SIMS) and laser confocal microscopy indicated that enzymes were immobilized within solid fibers as well as within microbead structures distributed throughout the webs. Degradation studies of CALB-enzyme functionalized solution-blown nonwoven (EFSBN)-PCL webs at 40 °C or ambient temperature showed that EFSBN-PCL webs degraded rapidly when exposed to aqueous pH 8 buffer. Scanning electron microscopy (SEM) images of partially degraded webs showed that thinner fibers disappeared first, thus, controlling fiber dimensions could control degradation rates. Rapid degradation was attributed to the combination of nanofibrous web structure and the distribution of enzymes throughout the webs. CALB immobilized in the solid dry webs exhibited long storage stability at room temperature or when refrigerated, with around 60% catalytic activity being retained after 120 days compared to the initial activity. Dry storage stability at ambient conditions and rapid degradation upon exposure to water demonstrated that EFSBN-PCL could be used as fibers or binders in degradable textile or paper products, as components in packaging, for tissue engineering and for controlled-release drug or controlled-release industrial and consumer product applications.

1 year ago

68

1 year ago

68