Materials, Vol. 16, Pages 4128: Microstructure and Recrystallization Behavior of Heating Rate-Controlled Electrolytic Capacitor Aluminum Foil under Cold Forming and Annealing

Materials doi: 10.3390/ma16114128

Authors: Yunlei Wang Taibin Wu Luchang Che Guangjie Huang

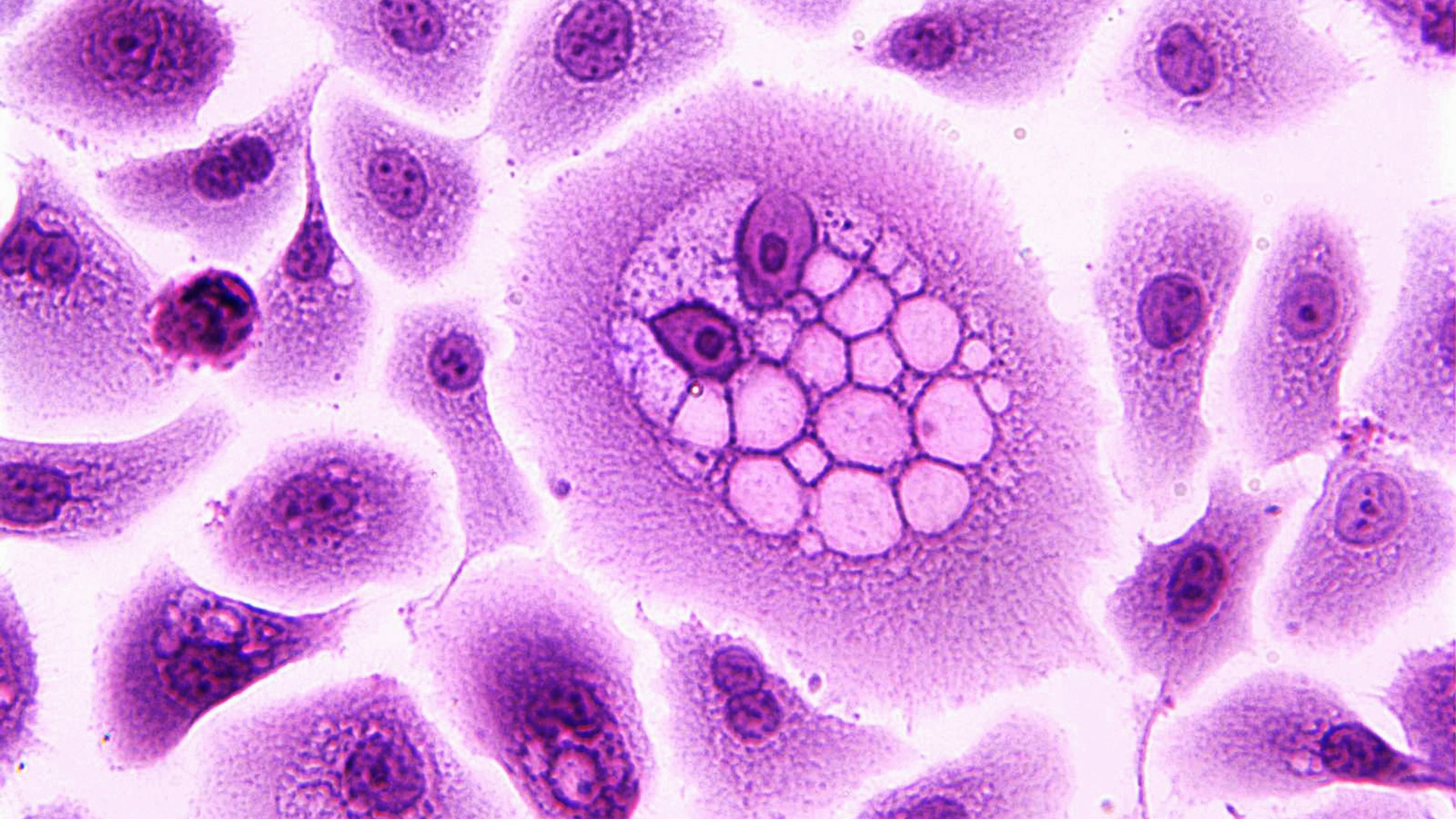

A novel annealing process of controlled heating rate is used to produce severe cold-formed aluminum plates, which are processed into aluminum foil and mainly used for high-voltage electrolytic capacitor anodes. The experiment in this study focused on various aspects such as microstructure, recrystallization behavior, grain size, and grain boundary characteristics. The results revealed a comprehensive influence of cold-rolled reduction rate, annealing temperature, and heating rate on recrystallization behavior and grain boundary characteristics during the annealing process. The heating rate applied plays a crucial role in controlling the recrystallization process and the subsequent grain growth, which ultimately determines whether or not the grains will become larger. In addition, as the annealing temperature rises, the recrystallized fraction increases and the grains size decreases; conversely, the recrystallized fraction decreases as the heating rate increases. When the annealing temperature remains constant, the recrystallization fraction increases with a greater deformation degree. Once complete recrystallization occurs, the grain will undergo secondary growth and may even subsequently become coarser. If the deformation degree and annealing temperature remain constant, the increased heating rate will result in a lower recrystallization fraction. This is due to the inhibition of recrystallization, and most of the aluminum sheet even remains in a deformed state before recrystallization. This kind of microstructure evolution, grain characteristic revelation, and recrystallization behavior regulation can provide effective help for enterprise engineers and technicians to guide the production of capacitor aluminum foil to a certain extent, so as to improve the quality of aluminum foil and increase the electric storage performance.

1 year ago

26

1 year ago

26