Processes, Vol. 11, Pages 2968: Structure Characteristics and Removal Behavior of the Deposited Carbon on Ni-Al2O3 Catalyst for CO2 Reforming of CH4

Processes doi: 10.3390/pr11102968

Authors: Wen-Long Mo Yuan Ren Yaya Ma Jing Guo Zhi-Hui Feng Shu-Pei Zhang Xiao-Qin Yang

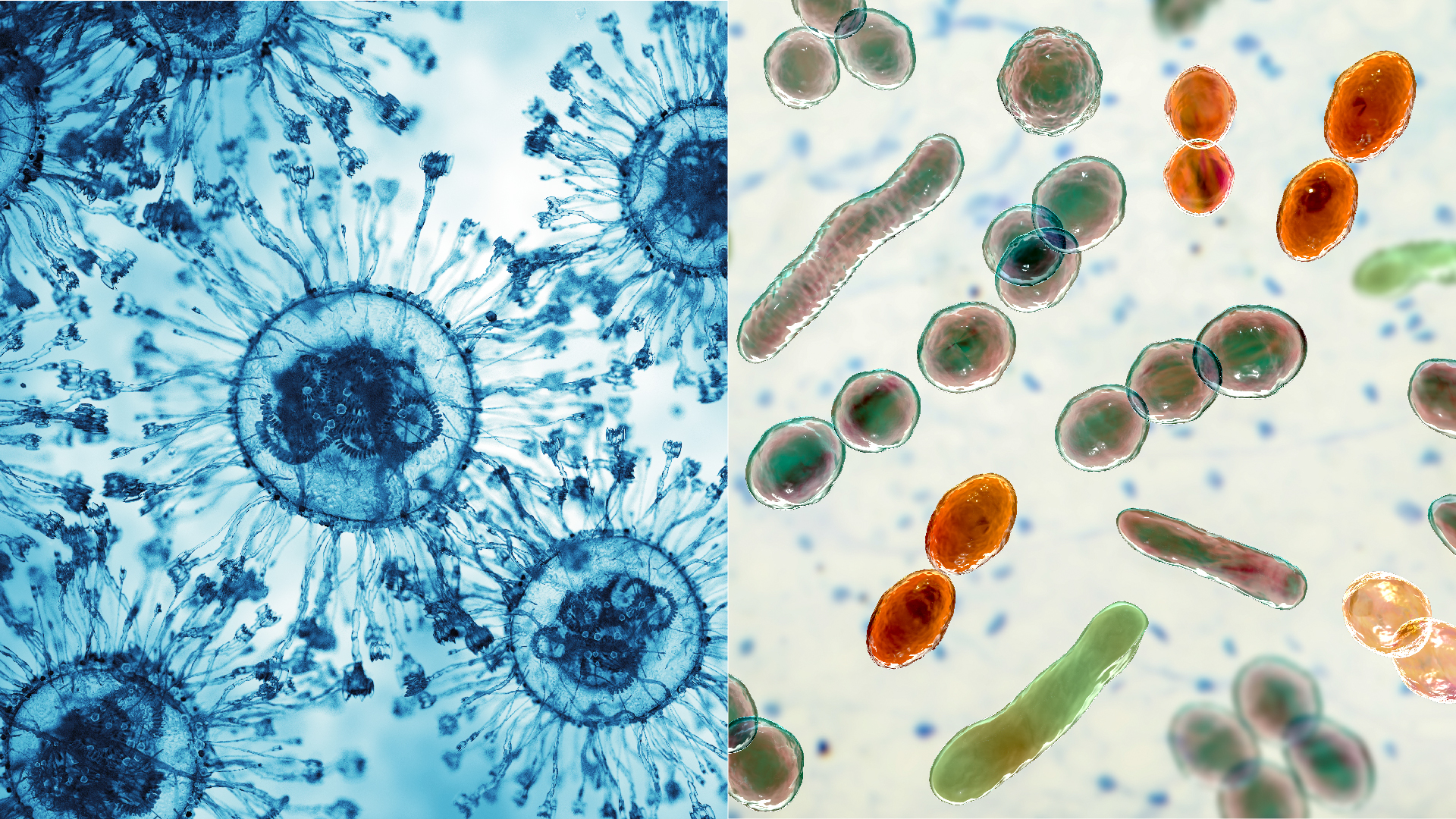

Four catalysts were prepared in our previous work using the solution combustion method, incipient-wetness impregnation method, colloid mill circulating impregnation method, and hydrothermal-precipitation method, respectively, labeled as SCM, IMP, T310, and HTP. And the performance (stability) of the four catalysts for CO2 reforming of CH4 was investigated at 800 °C. In this paper, the composition and structure characteristics of the deposited carbon on the above four catalysts were tested through TEM, Raman, TPH, and TG-DTG technologies. The results showed that filamentous carbon was the primary type of carbon deposition on the catalysts, and a large amount of accumulated carbon would block the catalyst pores, affecting the catalytic performance. The carbon deposited on the catalyst prepared using the hydrothermal-precipitation method calcined at 800 °C exhibited a high degree of graphitization, and the proportion of graphitized carbon was considerable, which is harmful to the stability of the catalyst. The decarburization temperature of the deposited carbon on the four catalysts was mainly in the range of 500–700 °C. Using the Coats–Redfern model, as the reaction order was set as 1, 2, 3, 4, and 5, the decarburization activation energy ranged between 50 and 80 kJ/mol.

1 year ago

23

1 year ago

23